Where Innovation Meets Excellence

Sludge Dewatering

Where Innovation Meets Excellence

Sludge Dewatering

Are you looking at dewatering or thickening your sludges to reduce costs of disposal?

Are you under pressure from Environmental Bodies reducing spreading to land times?

Did you know that sludges from your DAF or Clarifier are typically only up to 5% solids?

You are tanker away 95% water on average.

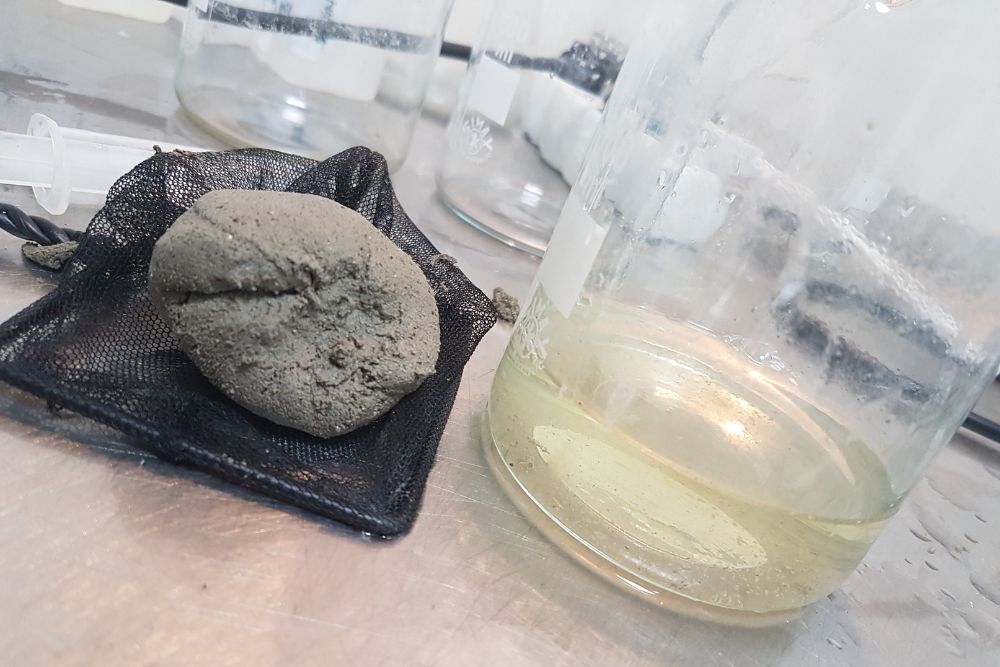

Sludge sample jar test – polymer selection, liquid/solid separation, and squeeze test.

We have 15 years of experience in polymer selection and dewatering.

We have access to dewatering trial units should you be looking at the next step of investing in

equipment to reduce disposal costs.

We also have access to rental units should you be looking at longer term trials before making your

decision or typically a weeks trial to confirm data and cost savings.

Brewery wastewater treatment plant – Aerobic & Anaerobic settled bio solids combined, passed through a moving plate screw press.

Cooked meat process water. Sludge produced from a DAF treated with Ferric and cationic polymer. The polymer selection was more difficult as a cationic polymer is used for dewatering.

A sludge sample jar test demonstration – polymer selection, liquid/solid separation. A view of how the polymer continues to release the water phase while holding the solid phase together.

talk to us

Connect with

Stuart Garton

+44 (0) 1530 234 805

Need a quote for your organisation? Contact us today and we’ll get back to you within 24 hours.

let’s get connected

Have a Question?

Get in touch with us today and we’ll get back to you within 24 hours.